Engineers and scientists from the University of Bath are aiming to produce the first yeast-derived alternative to palm oil on an industrial scale in a move that could open up a new front in the battle against climate change.

Palm oil is used in a huge range of products from biofuels to cakes, biscuits and instant noodles and in cosmetic products spanning lipstick to shampoo.

Some 60m tonnes of palm oil are produced each year globally with more than 40m tonnes exported to more than 70 countries worldwide.

But massive worldwide demand for the oil has led to severe deforestation in South East Asia, water pollution, increased greenhouse gas emissions and heavy smog pollution across the region.

The palm oil substitute being developed by the Bath researchers working with scientists from the University of York is based on a novel yeast grown using sustainably-sourced waste feedstocks.

The team has been awarded a £4.4m grant to allow them to build on their earlier lab-based findings and look at ways of producing this palm oil alternative on an industrial scale.

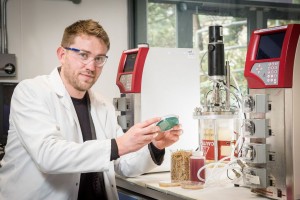

Previous work at Bath found that the yeast Metschnikowia pulcherrima can be grown under non-sterile conditions on a variety of agricultural and food wastes, and with slight changes to the growth conditions, the yeast can be made to produce a thick oil.

The Bath team includes experts from the university’s departments of chemical engineering, mechanical engineering, and biology & biochemistry, who will work with the University of York’s Green Chemistry Centre of Excellence and industry partners Croda, C-TECH and AB Agri.

The oil produced by Metschnikowia pulcherrima has nearly identical qualities to palm oil and the researchers are confident that it could lead to a home-grown direct replacement, mitigating the environmental issues associated with palm oil production.

The researchers will now apply an innovative method of depolymerizing waste feedstocks using efficient large-scale microwave heating at the University of York. The Bath team will improve the genetic understanding and control of this novel yeast, scale the fermentation up to an industrial scale and assess the total environmental impact across the life cycle.

Lead researcher Dr Chris Chuck, pictured, who is Whorrod Research Fellow in the Centre for Sustainable Chemical Technologies (CSCT) and lecturer in the Department of Chemical Engineering said: “This project is an exciting opportunity for us to develop a renewable alternative to palm oil, while developing further sustainable technologies that could have a significant impact on many other UK sectors.”

The four-year project has been jointly funded by BBSRC, EPSRC and Innovate UK as part of the Industrial Biotechnology Catalyst Programme aimed at supporting the development and commercialisation of innovative processes in industrial biotechnology

Research carried out by the University of Bath’s Department of Chemical Engineering was ranked sixth nationally for impact by the 2014 Research Excellence Framework, an independent assessment of UK university research activity.